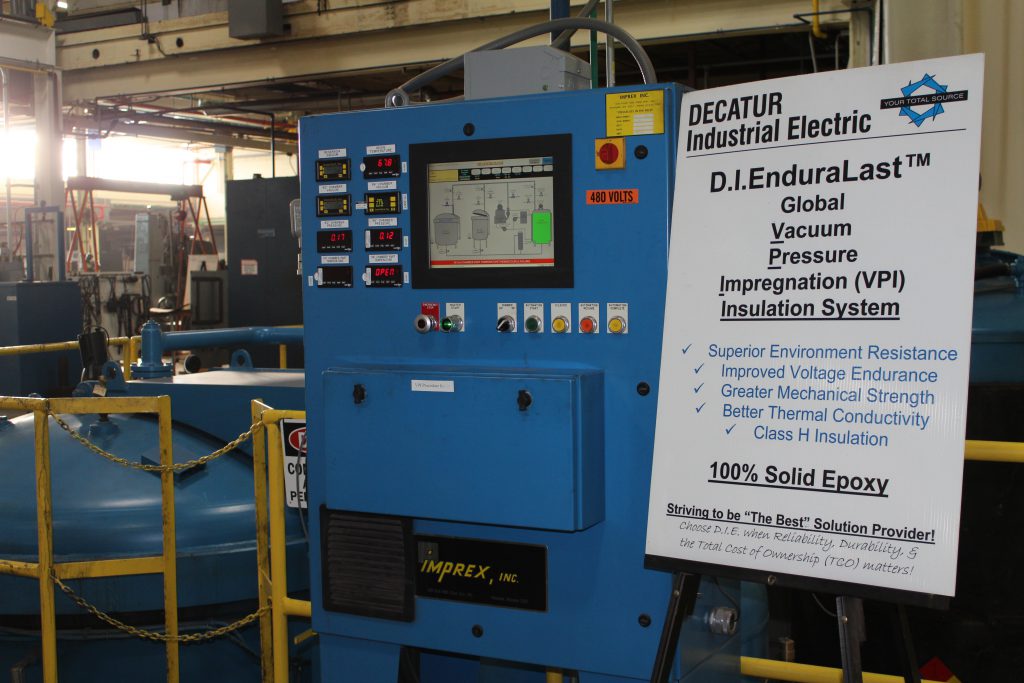

Resin Vacuum Pressure Impregnation

Since 1985, we have used Vacuum Pressure Impregnation (V.P.I.) to remove air, moisture and volatiles from windings, and to provide more thorough impregnation with conventional dip & bake processes. The pressure cycle leaves no voids, deep penetrating channels, or a weak structure.

Our automated global premium designed insulation system has been designed and tested to withstand a wide range of conditions, along with thermal shock and voltage stress.

- Superior environment resistance

- Better thermal conductivity

- Greater mechanical strength

- Improved voltage endurance

- Class H insulation available

- High bond strength