Decatur Industrial Electric Takes on Double Drum Dryer Project

(Scroll to bottom for images!)

A Decatur Industrial customer was looking for a vendor to rebuild a piece of equipment for their joint venture partner. The turned to us – already one of their strategic partners with the ability to meet the demands and requirements:

- Extensive mechanical and electrical knowledge

- 35 ton crane capacity

- Read and interpret OEM blueprints and electrical diagrams

- Complete machining capabilities

- Garage bay door up to 14’ wide and 16’ tall

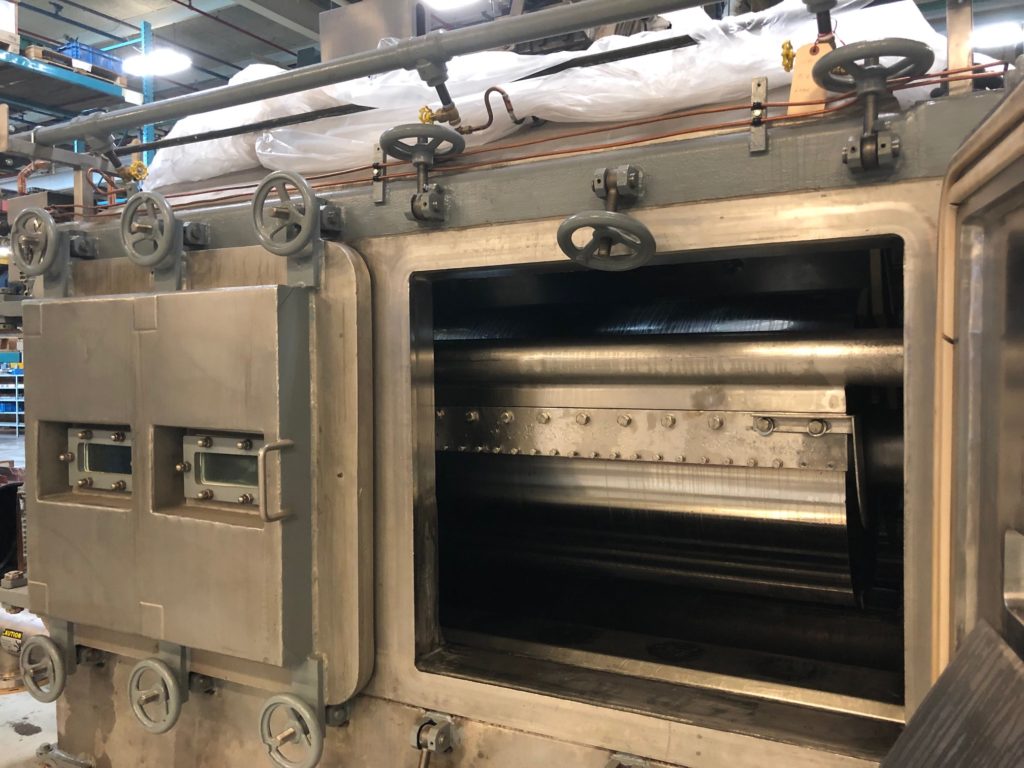

This customer and their joint venture partner had a new product they wanted to create and sell; and couldn’t do so without a double drum dryer. Our team of experts took the reins and handled the project from start to finish. This project was a perfect fit for our capabilities, especially in our machine shop.

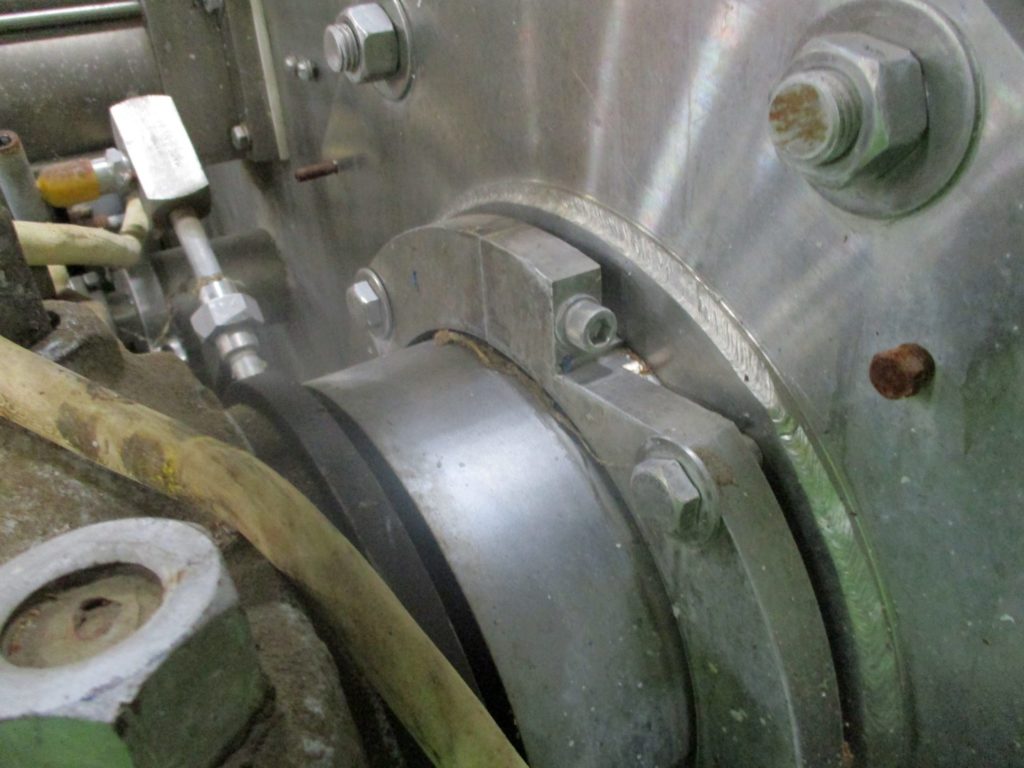

Utilizing the OEM manuals, we began with disassembly just like our typical process. However, unlike a typical motor, this disassembly process was much more complex as the number of components was multiplied. This project saw us disassembling and assembling: bearings, rolls, end plates, packing glands, gears, cutter arms, air cylinders, air lines, adjuster arms, sprayer arms, door clamps, and more.

Our machine shop also handled:

- Machining all rotating parts to within tolerances

- Repairing bearing journals on drums

- Manufacturing teflon brushings and bronze bushings

Weighing in at over 30,000 pounds and encompassing a footprint of 11 feet by 10 feet, this repair saved the customer $400,000 versus buying a refurbished one. The customer realized a significant cost savings.

Do you have a unique piece of rotating equipment that needs repaired? Call the experts at Decatur Industrial to come take a look.

Click on image to enlarge.