Learn more about this opportunity by clicking here for the full job description.

Vertical Motor Training Class: Thursday, January 18

US Motors and NIDEC Presents: Vertical Motor Training @ Decatur Industrial Electric

The class will be from 10 AM to 2 PM CST. Lunch is provided.

The class is FREE to customers but must RSVP before spots fill up. Email rsvp@decaturindustrial.com

“It’s Junk?!”

How Could a 200 Horsepower Motor Not Be Worth Repair?

It happens. There are times when our service center must tell a customer that their 200hp motor is just not worth repairing. Extreme damage from the motor failure may make the motor not economical to repair (NER); however, there are other times when it’s just not a good business decision to repair.

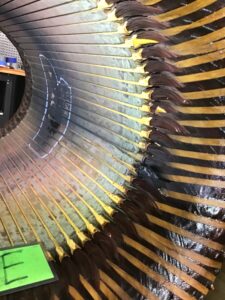

Our goal is to provide our motor owners with a reliable repair that is as good as new, or better in many cases. In this case study, the motor had suffered many previous insulation failures to ground and it absolutely could have been rewound economically. However, even though the damage was not visible, proper coreloss testing revealed the laminations were shorted. When this occurs, the motor loses performance, efficiency, and will eventually suffer a failure in the stator hot-spot area.

This customer at first didn’t understand why we recommended recycling the motor because they had it repaired by another shop several times. However, after an inspection review with the customer of the test results and quality concerns, the customer researched the motor history and found that the motor had been rewound not only several times, but also less than 6-months ago.

As Strategic Partner’s in Reliability Performance, it’s D.I.E.’s job to help our customers make good business decisions with their critical motor assets. Decatur Industrial now offers the full range of Toshiba motors and drives and was able to provide the customer a new energy efficiency “drop in” replacement Toshiba motor solution.

Hidden Damage = Poor Reliability!

Click on the image to enlarge in a new window.

Is it the Pump or the Motor?

In the classic battle of root cause analysis, it often comes down to electrical vs. mechanical with the motor or the pump being the primary suspects. A variety of tools may be utilized to assist in the investigation including electric motor testing, infrared thermography, vibration analysis, ultrasonics and even oil analysis. Although these technologies have their primary uses they can often cross halfway over the “correlation bridge” and offer a look from the other side. As an example, it has become a common approach to use electric motor test equipment like the MCEMAX® or PdMAEYE to evaluate the machine train performance in areas involving pump vanes, fan blades, belts, gears, and fluid flow. Changes in the asset health of these machine train components will affect the current and torque requirements of the motor and provide valuable data analysis tools for the root cause analysis.

To see the MCEMAX® technology used to identify a machine train anomaly on a critical pump visit the PdMA YouTube site at https://www.youtube.com/watch?v=HxjitFVIehI

Webinar Opportunity! Toshiba: Starter Applications Methods of Starting Induction Motors

Thursday, August 31: Noon to 1 PM

The webinar will cover:

- Applications and reasons for soft starters to replace traditional starting methods. (Toshiba solution)

- Application and reasons to use a variable frequency drive in place

of a soft starter. (Toshiba solution)

- « Previous Page

- 1

- 2

- 3

- 4

- 5

- 6

- …

- 15

- Next Page »