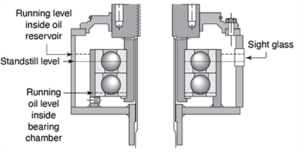

The sight glass of vertical machines has two marks, either marked as “Min” and “Max” or “Standstill” and “Running.” Sometimes, as shown in Figure 1, it’s not marked at all. There is much confusion about how to interpret these levels, and the motor manufacturer manuals are consistently vague.

Unlike the dipstick in an automobile engine, the marks are not indicative of a safe range. The cutaway view of Figure 2 helps clarify how we should view those levels. The higher mark, whether it is labeled “Max” or “Running,” is the oil level we should see when the motor is running.

As Figure 2 indicates, oil inside the bearing chamber is metered to avoid flooding the bearings during operation, which results in a higher oil level at the sight glass.

The lower mark, “Min” or “Standstill,” is the oil level when the motor is not running. The oil seeks its own level, partially flooding the bearings within the inner chamber, to protect the bearings against corrosion.

If we carry this understanding a step further, a running motor with oil level at the lower mark means the standstill oil level will be even lower – by the distance separating those two marks. Worse still, a non-rotating motor with oil level at the upper mark is actually overfilled, and the running level will increase by the distance between those two marks. In that case, an oil leak is very likely to occur when the motor is running. For more valuable resources, check out the EASA Resource Library